A new level of perfection

The SynchroFeed process

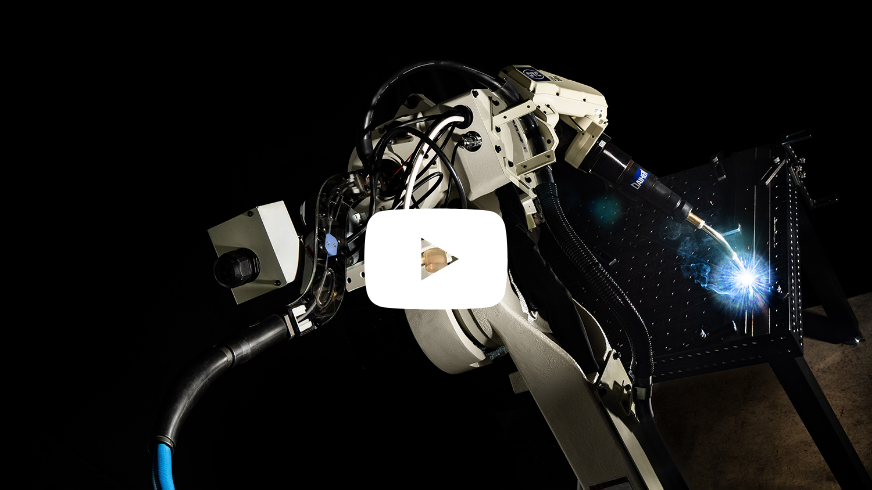

The SynchroFeed welding process developed by OTC DAIHEN in 2016 enables:

- higher welding speed

- drastically reduced heat input

- extremely low weld spatter formation

Based on the peak dip transfer process (PDT process), which realizes a controlled drop transfer in the short circuit phase, the servo-driven wire feeding system is designed with a cyclic retracting controlled wire movement and the intelligent wire buffer for a perfect welding result.

Inquire now

SynchroFeed Evolution

Proven technology with new features

With SynchroFeed Evolution, OTC DAIHEN could expand the range of applications drastically:

- Pulse welding for use with thicker plates

- Push Arc welding for a flatter welding seam

- AC/MIG welding for gap bridging with thin aluminum sheets and different sheet thicknesses

SynchroFeed Evolution

Two variants

- Multiple usage of power sources (P402L, P502L, W400)

- Combination of SynchroFeed with AC/MIG

- Suitable for aluminum alloys, mild steel, stainless steel, non-ferrous alloys

- Entrance version of SynchroFeed

- Upgrade to SynchroFeed Pro possible

- Developed for mild steel and stainless steel welding

Contact